Home / Technology / Apple Slashes Waste with 3D-Printed Titanium Watches

Apple Slashes Waste with 3D-Printed Titanium Watches

19 Nov

Summary

- Apple Watch cases are now 3D printed using 100% recycled titanium powder.

- This new 3D printing process cuts raw material usage for cases in half.

- Apple saved an estimated 400 metric tons of titanium this year.

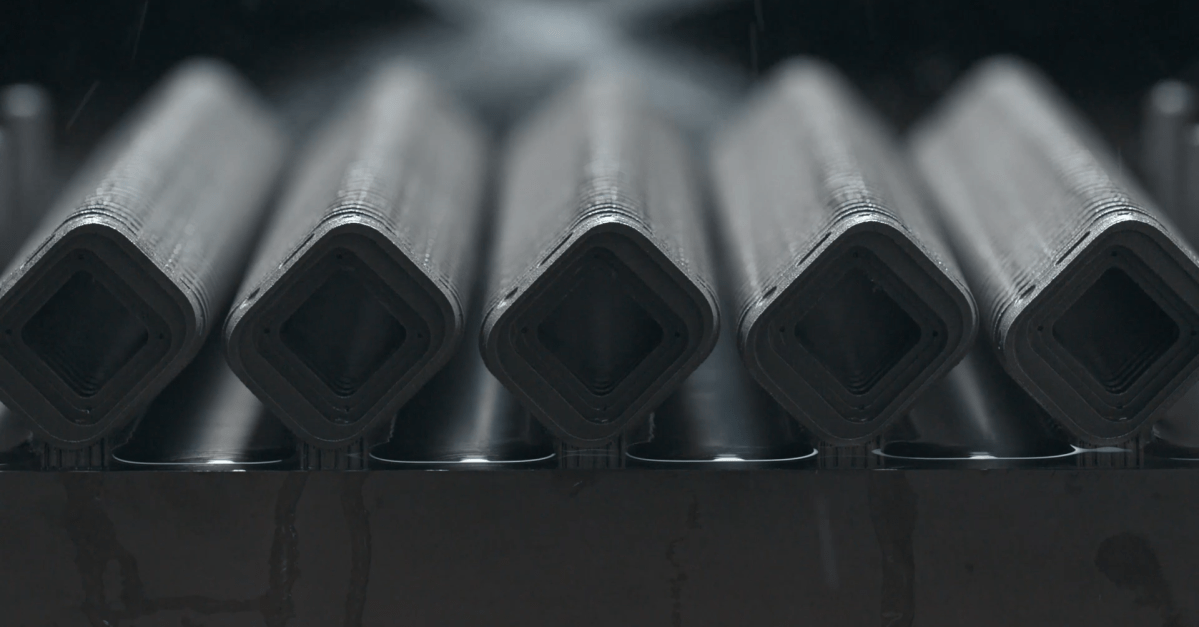

Apple has embraced advanced manufacturing by introducing 3D-printed titanium cases for its latest Apple Watch Series 11 and Ultra 3 models. This groundbreaking process uses 100 percent recycled titanium powder, blasted with a laser over 900 layers to form each case. This method dramatically cuts raw material usage in half, demonstrating Apple's dedication to sustainability and innovation.

The transition to 3D printing, rather than traditional subtractive manufacturing, has yielded significant environmental benefits. Apple estimates it has saved approximately 400 metric tons of raw titanium this year alone. This process, while impressive in its scale and precision, also presents challenges in balancing speed and material integrity.

Further integrating this technology, Apple has also applied the 3D printing process to the USB-C port on the iPhone Air. While a full iPhone chassis is not yet 3D printed, the company's vice president of Environment and Supply Chain Innovation indicated a broader adoption of such sustainable practices across its systems.