Home / Sports / 3D-Printed Spikes: BMW's Secret for Bobsled Dominance

3D-Printed Spikes: BMW's Secret for Bobsled Dominance

15 Feb

Summary

- BMW innovates bobsledding with custom 3D-printed studded shoes.

- German athletes excel due to tradition and technological focus.

- Sled weights are regulated to ensure fair competition among athletes.

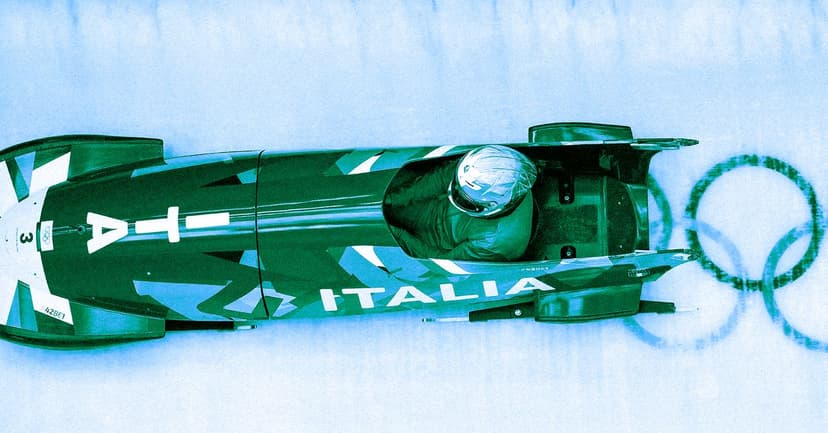

Bobsledding, often likened to "Formula 1 on ice," involves high speeds and intense gravitational forces. For the 2026 Milano Cortina Winter Games, technology is being employed to refine every race phase. The sport, which debuted men's four-person in 1924 and women's two-person in 2002, has seen materials evolve from wood to carbon fiber for improved strength and lightness.

Safety constraints, including weight and sled size limits, are integral to technological advancements. A two-person sled has a maximum length of 2.7 meters and a weight of 390 kilograms, while a four-person sled can reach 3.8 meters and 630 kilograms. These regulations aim to equalize conditions and prevent undue reliance on non-bobsledder specialists for the push phase.

Germany has a strong bobsledding tradition and a focus on innovation, leading to significant success, including 16 medals from bobsled, luge, and skeleton at the 2022 Beijing Games. Automaker BMW's partnership with the German federation has introduced crucial innovations like custom studded shoes. These shoes, manufactured using 3D printing, allow for rapid design experimentation and adaptation of stud stiffness and shape.

Innovations in footwear, specifically the first 30 to 50 meters of the race, are vital for acceleration. BMW's custom spike plates, integrated into shoes and hardened via plasma nitriding, are designed to enhance this critical pushing phase, showcasing how targeted technology can impact athletic performance.