Home / Science / New Laser Patterning Speeds Heat Control

New Laser Patterning Speeds Heat Control

18 Jan

Summary

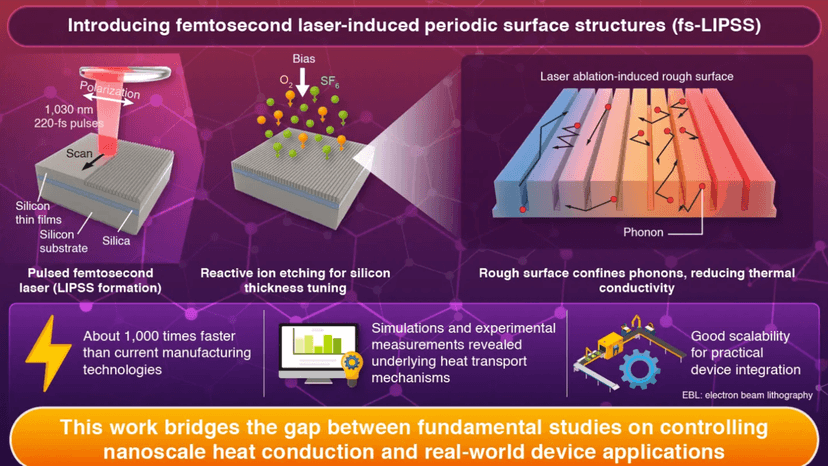

- Ultrafast lasers create nanoscale surface structures on silicon films.

- Method controllably alters how heat moves through chip materials.

- Process is over 1000x faster than electron-beam lithography.

Engineers in Japan have devised an innovative technique that utilizes ultrafast laser pulses to modify the thermal properties of silicon and silica films at the nanoscale. By creating precisely spaced grooves on material surfaces, the method controllably alters how heat travels through electronic components, moving beyond traditional heat removal strategies.

This femtosecond laser-induced periodic surface structure (fs-LIPSS) process achieves nanoscale resolution at speeds more than 1000 times faster than single-beam electron-beam lithography. It is maskless, resist-free, and scalable for wafer-level implementation, aligning with current CMOS manufacturing standards and enhancing mechanical robustness.

The advancement holds significant promise for high-performance computing, quantum devices, and thermal management in dense GPU clusters for AI. Wider adoption will hinge on industrial-scale reproducibility, long-term stability, and cost-effectiveness, paving the way for more efficient electronics.